Technology Innovation Self-design

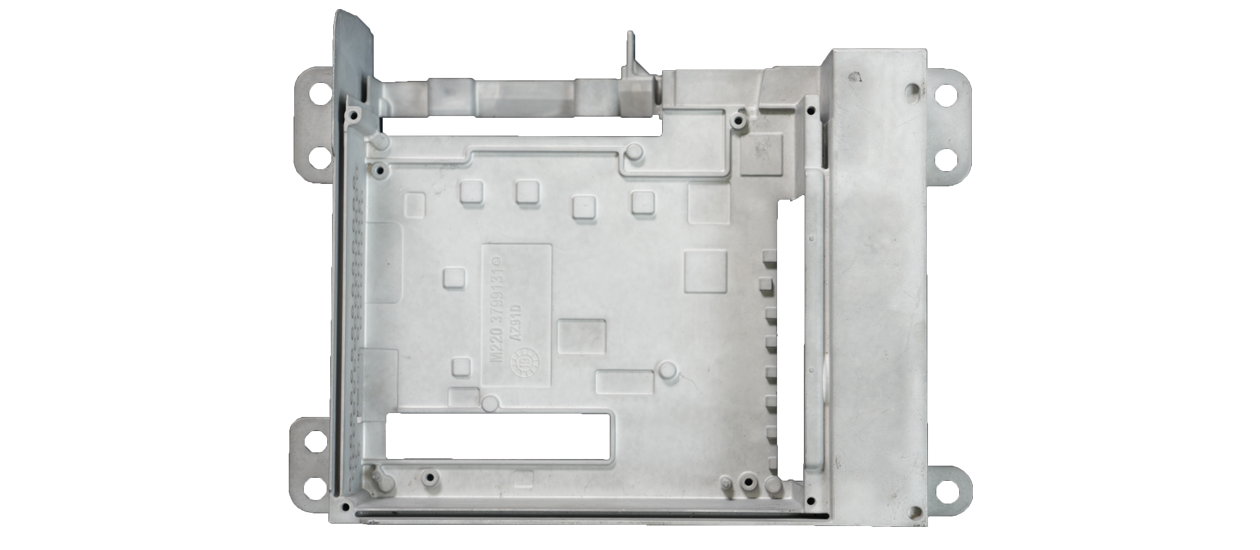

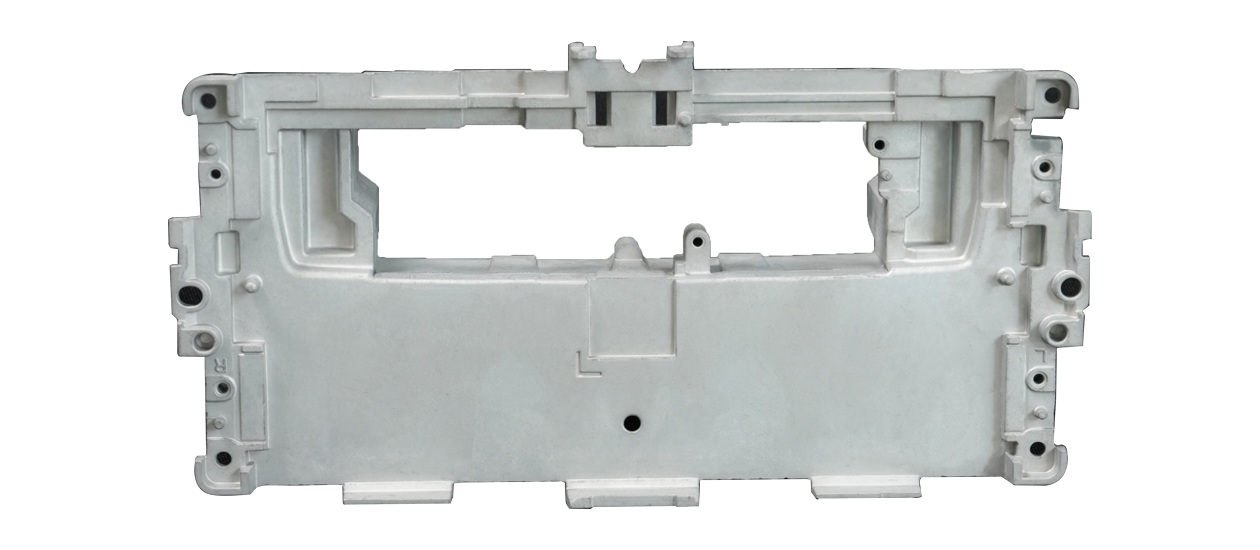

/R&D/Production Mold Solutions

With our own mold department and workshop, we have the advantage of in-house production of the entire mold process,

responding quickly to ENC change and other design changes, and achieving the completion of soft molds in 2 to 4 weeks, and hard molds in 3 to 6 weeks.

We have the ability to deliver soft molds in 2 to 4 weeks and hard molds in 3 to 6 weeks,

providing customers with highly flexible and high quality support services during the development process.