Automated One-Stop Die Casting Production: Fulltech Casting's Vertical Integration Advantages and Technological Innovations

Introduction:

The one-stop production model, also known as vertical integration, involves creating a closed-loop system aimed at continuously improving quality management and production capabilities.

This model centers around the product, expanding upstream to transportation, raw material management, and supply, and downstream to reprocessing, agents, distributors, and retailers, all managed by the company’s own team. This approach achieves optimal vertical integration within a single product category, creating greater profit margins. The integration involves numerous details and technical aspects; the higher the integration, the greater the complexity and the corresponding benefits, which is why many large corporations pursue this direction.

Most purchasing officers, when ordering customized aluminum, magnesium, and zinc alloy die-cast products, prefer manufacturers with high vertical integration, also known as one-stop production facilities, because this model simplifies many processes, such as transportation and manual handling. It reduces indirect costs of labor, resources, and time, as well as uncontrollable risks during transfer, and the uncertainty of accountability, thereby enhancing production scheduling, improving delivery rates, and increasing quality yields.

Technical Services:

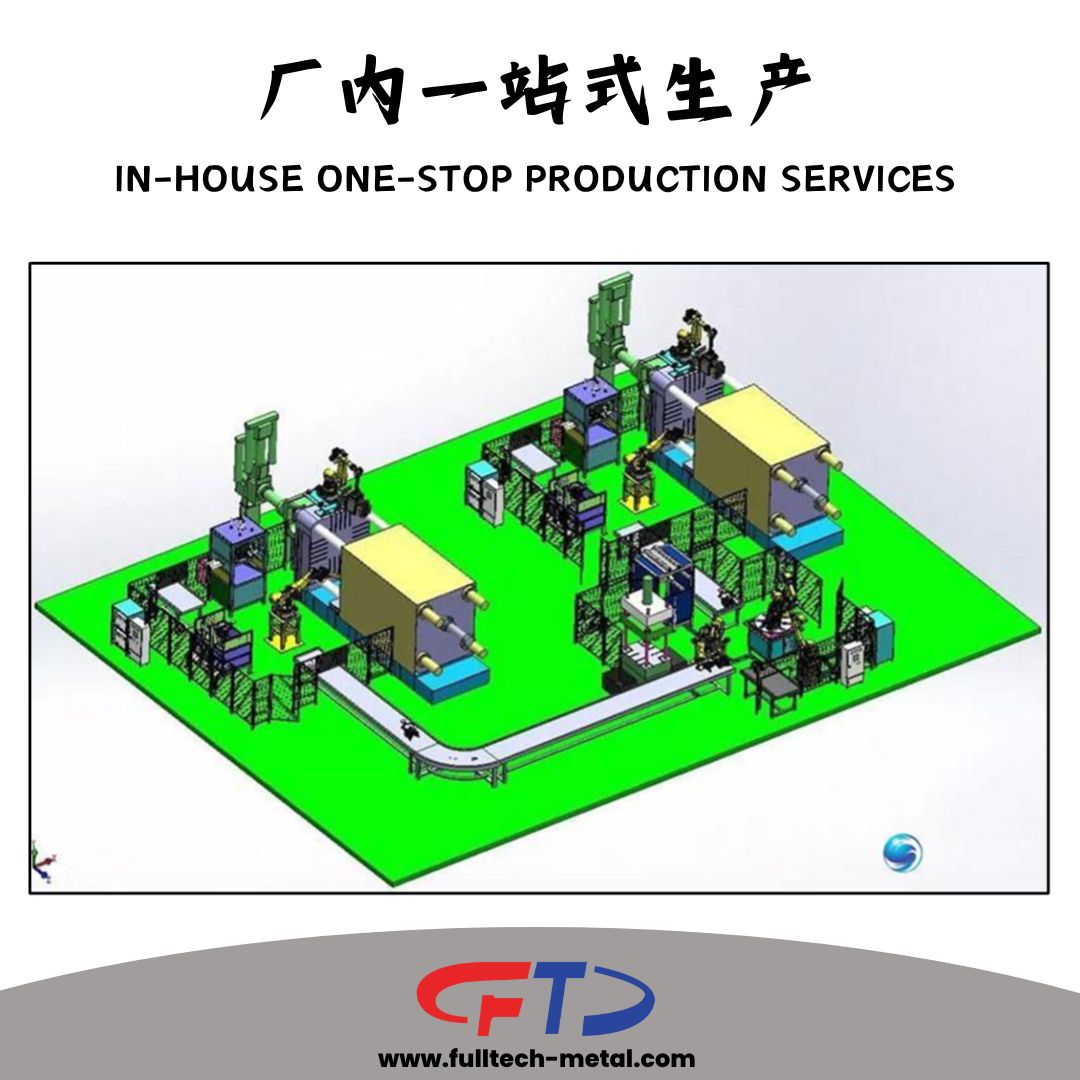

Fulltech Casting provides in-house one-stop production services, managing material scheduling and quality control, including complete mold and fixture design. Established in 2017, our automation team has developed several continuous flow production lines, reducing costs while improving die-cast quality and yield, thereby enhancing our competitive edge. Leveraging proprietary technology, we have established fully automated production lines. The process flow is as follows:

Die Casting → Trimming → Deburring → Drilling and Tapping → CNC Machining → Cleaning → Film Treatment → Powder Coating → Connector Assembly

Advantages of Single-Piece Flow:

- Significantly shorter production cycles and faster material turnover.

- Higher product quality stability and improved yields.

- Reduced manpower needs, saving labor costs.

- Decreased production area required, reducing the amount of work-in-progress materials.

- Lower comprehensive product costs, enhancing price competitiveness.

Conclusion:

Fulltech Casting primarily engages in aluminum, magnesium, and zinc alloy die casting and processing, from mold opening and die casting to CNC machining and surface treatment. With our own surface treatment department, we greatly reduce delivery times. In terms of quality control, Fulltech Casting maintains a comprehensive management system and testing equipment. Each step of the process is closely monitored by dedicated personnel who conduct full inspections and random in-line checks to minimize uncertainties, promptly identify and resolve issues, ensuring product quality. For custom mold inquiries, please contact us.